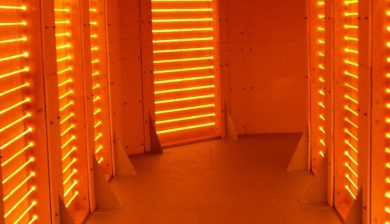

Strip Hardening and Temper Furnaces

Wet shaving blade heat treat line includes silicon carbide industrial hardening furnace and tempering industrial oven.

Infrared Heating Technologies (IHT) manufactures strip hardening furnace and temper oven lines for wet shaving blade heat processing. These systems implement electric silicon carbide and standard sheathed resistive heating elements, multiple heat zones, and multiple alloy processing tubes.

The hardening furnace and temper oven systems are custom designed to harden and temper from two to eight strands of stainless steel shaving blade strip steel in a continuous process. The hardening furnace system is designed to heat the strip for quench hardening. The hardening furnace section has a maximum temperature of 2,100 Deg F and is divided into several independently controlled heat zones for a specific temperature profile. The tempering oven section has a maximum temperature of 1,200 Deg F and is divided into several independently controlled heat zones for tempering/annealing the strip to reduce brittleness after the hardening step. These furnace and oven systems include complete PID temperature and SCR power controls and can be provided with PLC and HMI controls for recipe generation and communications.

Furnace and Oven Features and Options

- Silicon Carbide Heating From Top And Bottom

- Multiple Inconel Alloy and Stainless Steel Processing Tubes

- Gas Control

- SCR Power Controls

- PID Temperature Controls

- Multi Zone Control

- Clamshell Design

- PLC and HMI Control

Applications and Processes

- Wet Shaving Blade Heat Treatment

- Strip Hardening

- Strip Annealing

- Strand Annealing

- Wire Annealing