Explore all the products, processes and industries we help:

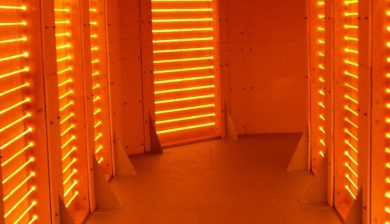

Infrared Quartz Lamps and Heaters

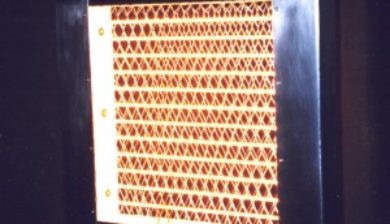

The standard T3 style short wave infrared heat lamp is a high intensity infrared heating element measuring 3/8″ in quartz diameter. This heat lamp provides short wave (1.2 micron peak) infrared radiation with tungsten element temperatures up to 4,000°F. These infrared quartz lamps are available in several lighted and overall lengths with wattages ratings of 100-200 watts per linear inch.

The standard T3 style short wave infrared heat lamp is a high intensity infrared heating element measuring 3/8″ in quartz diameter. This heat lamp provides short wave (1.2 micron peak) infrared radiation with tungsten element temperatures up to 4,000°F. These infrared quartz lamps are available in several lighted and overall lengths with wattages ratings of 100-200 watts per linear inch.

We supply T3 infrared halogen lamps at the lowest possible pricing available anywhere.

Let The Experts in Infrared Heating Assist You In Determining The Right Infrared Quartz Lamps For Your Application.

Infrared Quartz Lamps Specifications

Short-Wave Halogen Quartz T3 Lamps

We supply Tungsten Halogen Infrared Heat Lamps in a wide variety of lighted/burn lengths, overall lengths, powers, voltages, end terminations, and quartz options.

The following represents only a partial listing of some of the more commonly used infrared lamps for infrared heating applications.

Description Watts Volts Overall Length Lighted Length

QHIT300T3/CL 300 120 8.47″(215.1mm) 4.19″(106.4mm)

QHIT500T3/CL 500 115 8.81″(223.8mm) 4.84″(123mm)

QHIT1000T3/CL 1000 200 13.81″(350.8mm) 10″(254mm)

QHIT1000T3/CL 1000 230 13.81″(350.8mm) 10″(254mm)

QHIT1600T3/CL 1600 200 19.81″(503.2mm) 15.75″(400mm)

Find the advantages, part numbers and product codes for Ushio IR Lamps.

Quartz Infrared Heater Element Advantages

- Very High Heating Rates. The extremely high source temperature of the tungsten filament leads to high thermal transfer and extremely fast heating.

- Fast Response. The low thermal mass of the tungsten filament gives outstanding control of the heat output and process temperature. Full output can be obtained within seconds of applied power. Also, power can be turned off almost immediately if production should stop.

- Controllable Output. Output can be controlled precisely to match the temperature requirements of the process.

- Directional Heating. Systems are able to selectively heat specific regions of the part.

- Clean Heating. Electric heat source is environmentally clean and efficient.

- High Heating Efficiencies. Up to 86% of input electrical power is converted to radiant energy (heat).