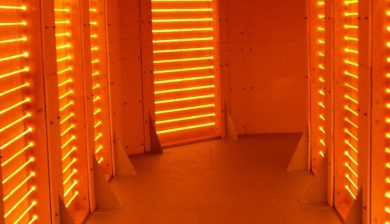

Temper, Anneal, and Stress Relieve Ovens

Infrared Heating Technologies (IHT) offers batch and conveyor temper and stress relieve furnaces. These temper furnaces are available in electric and natural gas fired. These standard and custom designed furnaces are designed for tempering and/or stress relieving in air and inert atmospheres. A wide variety of hearth configurations are available to accommodate the customers’ specific loading/unloading and part filtering requirements. Special high temperature alloy muffles and retorts are offered for those conveyor belt and batch temper processes requiring inert gas coverage.

The following lists some of the many temper and stress relieve processes for which our ovens have been implemented.

Temper, Annealing, and Stress Relieving Oven and Furnace Applications

- Stress Relieve Garage Door Extension and Torsion Springs

- Stress Relieve Small Springs

- Temper Brass Casings

- Stress Relieve Plastics

- Temper Strip

- Stress Relieving Wet Shaving Blade

- Wire Annealing

Temper, Annealing, and Stress Relieving Oven and Furnace Options and Features

- Electric Medium Wave Heaters and Short Wave Infrared Heaters

- Standard Resistive Coil Heaters

- Natural Gas Fired

- Infrared and Infrared/Convection Combination Systems

- Batch and Conveyor Systems

- Alloy Retort and Alloy Muffles

- Alloy Mesh and Flat Wire Belts

- Controls with PLC and HMI

- Maximum Temperatures 1,400 Deg F