Pre-Heat Ovens

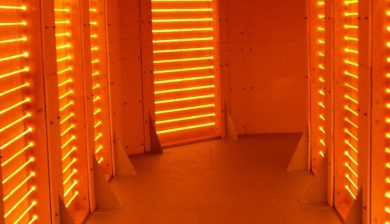

High intensity shortwave electric infrared tunnel. Process is pre-heating water heater tanks prior to foaming.

Infrared Heating Technologies (IHT) designs and manufactures electric Infrared Pre-Heat and Infrared Convection Combination Ovens for pre-heating parts and webs for a variety of processes including foaming, press forming, embossing, coatings, and other processes. These medium wave electric and high intensity short wave electric infrared pre-heat ovens offer a fast and efficient method to pre-heat parts and webs for a variety of processes. Infrared pre-heat oven benefits include increased line speeds and production throughputs, precise control of the heaters elements, multiple heat zones control, fast and efficient heating, and reduced floor space requirement. These electric infrared and electric infrared convection combination pre-heat ovens increase production for the smallest possible footprint.

The following lists some of the many pre-heat process for which our infrared heaters and furnaces have been implemented.

IHT Pre-Heat Oven Processes

- PEEK composites press forming

- Santoprene and MLT hose quench forming

- Glass matt thermoplastics (GMT) press forming

- Steel blank press forming and quench hardening

- Hot water tanks foaming

- Powder coat application

- Paint application

- Glass forming

- Vacuum forming

- Composite deck board embossing

- Aluminum billet press forming

- Aluminum sheet press forming

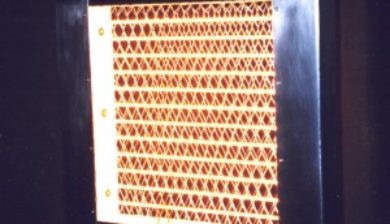

IHT Pre-Heat Heaters and Ovens Features

- Quartz Infrared Panel and Tubular Heaters

- Shortwave, medium wave, and long wave heaters

- Infrared and Infrared/Convection Combination Systems

- Chain, Slat, Chain-On-Edge, Flat Wire Belt, Flat Flex Belt, Teflon Belt, and Overhead Hanging Conveyors

- Controls with PLC and HMI