Infrared Ovens & Heaters

Infrared Heating Technologies is a leading manufacturer of electric infrared ovens and heaters. Infrared heating is the process of transferring heat or thermal energy by means of electromagnetic waves. Infrared radiation can be compared to visible light, microwaves, and x-rays. The shorter the wavelength the higher the temperature. Infrared provides a high burst of heat while also being very energy efficient. Infrared heaters are associated with high heating power and are beneficial when an application calls for a speedy response time switching on and off. IHT engineers design infrared oven systems with a peak radiation wavelength that matches the optimal absorption rate of the material or product to be heated.

The control of the infrared heating can be achieved using basic temperature controllers to a full PLC control system. Thermocouples can also be utilized to measure precise temperature.

IHT typically implements short wave infrared or medium wave infrared heating elements when designing a type of infrared oven system.

Short wave electric infrared heating elements employ a high intensity tungsten filament to transfer heat to the part. This heating element is sometimes referred to as a halogen lamp heating element due to the halogen cycle. Short wave elements operate at filament temperatures above 1800 °C. Advantages of short wave elements are: very high heat rates (up to 4000 Deg. F), fast response time, controllable output,directional heating, clean heating, and high heating efficiencies.

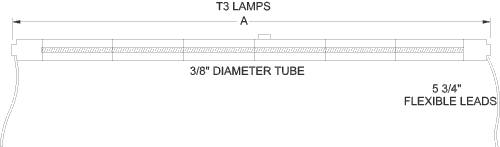

Medium wave electric infrared heating elements employ a NiCr wire element inside a quartz tube to transfer heat to the part. This heating element is sometimes referred to as a medium wave quartz tube element. Medium wave elements operate at filament temperatures of around 1000 °C Advantages of medium wave elements are: high heating rates (especially for drying), fast response, controllable output, clean heating and high heating efficiencies.

The choice of short wave or medium wave technology depends upon a number of factors related to the process and customer requirements. IHT engineer’s shall specify the element which is best suited to the specific application.