Call Us Today! 1-865-535-0050 | info@infraredheating.com

Electric Infrared – Short Wave and Medium Wave

Short Wave and Medium Infrared Emitters

Short wave electric infrared heating elements employ a high intensity tungsten filament to transfer heat to the part. This heating element is sometimes referred to as a halogen lamp heating element due to the halogen cycle. This heating technology has several features and related benefits:

- Very High Heating Rates: The extremely high source temperature of the tungsten filament (up to 4,000 Deg F) produces a wavelength of approximately 1.2 micron leading to very high thermal transfer and extremely fast heating.

- Fast Response: The low thermal mass of the tungsten filament gives outstanding control of the heat output and process temperature. Full output of our short wave electric IR ovens and furnaces can be obtained within seconds of applied power. Also, power can be turned off almost immediately if production should stop.

- Controllable Output: Output of our short wave electric infrared oven and furnace systems can be controlled precisely to

match the temperature requirements of the process. - Directional Heating: Short wave infrared oven and furnace systems are able to selectively heat specific regions of the part.

- Clean Heating: The short wave electric heat source is environmentally clean and efficient.

- High Heating Efficiencies: Up to 88% of input electrical power is converted to short wave radiant energy (heat).

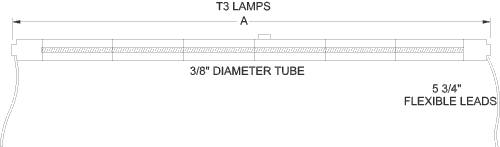

Medium wave electric infrared heating elements employ a NiCr wire element inside a quartz tube to transfer heat to the part. This heating element is sometimes referred to as a medium wave quartz tube element. This heating technique has several features and related benefits:

- High Heating Rates: The source temperature (up to 2,000 Deg F) of the NiCr element produces a wavelength of approximately 2.5 micron leading to high thermal transfer and fast heating. This medium wavelength is especially efficient for drying processes.

- Fast Response: The low thermal mass of the NiCr element gives very good control of the heat output and process temperature.

- Controllable Output: Output of our medium wave electric infrared oven and furnace systems can be controlled precisely to match the temperature requirements of the process.

- Clean Heating: The medium wave electric heat source is environmentally clean and efficient.

- High Heating Efficiencies: Up to 60% of input electrical power is converted to medium wave radiant energy (heat). Medium elements are particularly suited for drying applications due to the match of the emitted wavelength of the element with the absorption peak of water.

The choice of short wave or medium wave technology depends upon a number of factors related to the process and customer requirements. IHT engineer’s shall specify the element which is best suited to the specific application.

Infrared Heating Technologies, Inc

2010 HWY 58, Suite 2120 Oak Ridge, TN 37830

Phone: 1-865-535-0050

Email:info@infraredheating.com

Copyright © 2015-17. Infrared Heating Technologies, LLC.